We offer an extensive service along the entire process chain from the initial idea to the implementation and up to the product that meets the requirements. Process oriented project management, surface refinement, assembly as well as customer-specific logistics and supply concepts are part of our repertoire as a full-service provider.

Full service for complete process from inquiry to delivery

Purchasing / logistics

Close cooperation for strong services

We rely on long-term partners

In our eyes, a collaboration with suppliers that is trusting and partner-like is a central factor for success. For only together with our suppliers we can optimally satisfy the high demands of our customers. That is why we strive to develop close relationships with suppliers and to integrate these in our business processes. To do so, we acquire our purchasing parts and materials from component suppliers that have been carefully selected based on their technology, quality and costs. As a globally active company, we are especially interested in suppliers that can competitively provide world market standards and within that:

- demonstrate a quality management system setup as per ISO/TS 16949 as well as an environmental management system as per ISO 14001,

- act flexibly and punctually in response to stated needs,

- understand and already use Ship-to-stock (STS), Just-in-time (JIT) and KANBAN as instruments to optimize their stock,

- offer technical support and consultation,

- meet the preconditions for electronic data exchange,

- recognize the Schürholz contracts,

- accept the Schürholz guidelines for quality assurance as well as

- utilize production methods and materials that are environmentally friendly and support the goals of the Schürholz environmental management.

Purchasing portfolio

Purchasing portfolio

Our purchasing portfolio

The purchasing volume of the Schürholz companies worldwide amounts to more than 25 million euro. The largest portion is made up of production materials. The following pages allow you to view further information on the materials and components that we require.

Raw materials

Strips

- Hot rolled, hot-dip galvanized, stainless steel, aluminum

- Dimensions:

- Material thickness: 0.80 mm – 5.50 mm

- Material width: 17.10 mm – 345.00 mm

Sheet metal

- Cold rolled, hot rolled, hot-dip galvanized, electrolytically galvanized, stainless steel, aluminum, copper, brass

- Dimensions:

- Material thickness: 0.50 mm – 20 mm

- Material width: max. 1,500 mm

- Material length: max. 3,000 mm

Steel tubes

- Square, rectangular and round tubes

- Substance: steel, aluminum, VA

Lubricants

- emulsions

- special lubricants

Punch and drawn parts

punch and drawn parts

- Substance: spring steel, DC04, S355, 1.0718, H360LA, St 1403

extrusion parts

- Substance: 1.4567

Bolts, nuts

- bolts M6

- nuts SW17

Drawing parts, welded parts and press-in parts

- welding studs, welding nuts

- insert bolts, insert nuts

Services

surface refinement

- washing, degreasing

- hardening

- coating

mechanical processing

- sinking

- milling

freight

engineer services

personnel services

construction services

facility cleaning

gardening

etc.

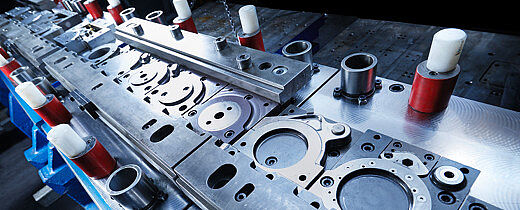

Production tools

- progressive and progressive purpose tools for punched parts

- edging tools

- punching tools

- press-in tools

Trade craft needs

- standard mold units and accessories

- cutting machining tools

- milling cutter

- drill

- thread cutting tools

- polishing tools

- grinding tools

- hand tools

- files

- tongs

- shears

- clamping systems

- workshop items

- welding and soldering material

- ball bearings

- fittings

- electric tools

- measuring tools and gauges

Work protection items

- shoes

- safety glasses

- hearing protection

- breathing masks

- gloves

- clothes

Packaging and printing materials

packaging and transport materials

- corrugated cardboard

- polyethylene film and bags

- adhesive tape

- wood, steel palettes and containers

printing items

- forms

- templates

- envelopes

- shipping documents

- perforated paper (labels)

Investments

machines and systems

properties and buildings

Supplier integration

An optimal exchange of information is necessary to integrate our supplier in our business processes. Business and CAD data are exchanged with our suppliers via a direct connection (EDI – Electronic Data Interchange) or through web portals. All electronic data exchange guidelines are applied for via the responsible purchasing sector.

EDI - direct connection for the data exchange

To exchange data by EDI, we prefer the route via ISDN (OFTP) or OFTP2. As an exception, there is also the option to connect via VAN or other encrypted processes. VDA and EDIFACT are use as the formats for the data exchange with component suppliers, while we prefer the VDA format.

Information regarding the parameters as well as the description of the single message type can be found in our download center.

Should you have further questions regarding the data exchange via EDI, please contact our hotline at +49 2391/ 8103 888.

Invoice by email

Link to the invoice form by email from accounting

External services

Strong partners for sustainable results

Surface treatments

- KTL coating

- zinc/nickel coating

- zinc/iron coating

- powder coating

- zinc flake coating

- manganese phosphating

- nickel plating

- chromium plating

Mechanical processing

- feed turned parts

- deep-drawing- & punch parts post-processing (turning)

- CNC turned parts

- sinking

Loading

- directly into small load carriers

- repackaging into special customer packages

- direct packaging in overseas packaging

Cleaning / vibratory finishing

- cleaning

- freedom from oil and grease (>40 mN/m)

- spraying process

- flood method

- vapor degreasing

- optional: temporary corrosion protection

- conservation with anti-corit

- vacuum drying

- vibratory finishing

- rotary vibrators

- tunnel machines

- rotomatic process

- continuous dryers (hot air)

- round and drum dryer (Maischschrot)

- ball polishing system (round vibrator and tunnel machine)

Supplier portal

WEBEDI – Portal for commercial data exchange

The WebEDI portal is a server-based web application, where the data of the procurement process (orders, delivery plants, credit notes, etc.) of Schürholz can be stored.

After logging in, these data can be printed or retrieved and saved in different formats (PDF, XML).

To register on this portal, a contact person has to be named (supplier administrator). The registration is done by means of a form (link to PDF form) and is activated by Schürholz. The data transmission is secured through an SSN encryption.

» Register for the supplier portal

Should you have further questions regarding the data exchange via EDI, please contact our hotline at +49 2391/ 8103 888.

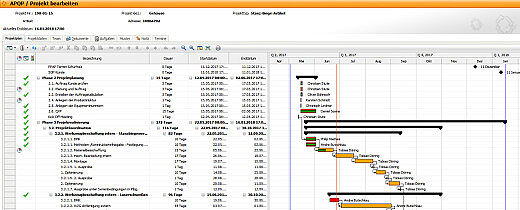

Process development / project management

From the idea to the product

Of course everything always starts with the customer’s demands, from which we then develop the necessary process steps and tool concepts using cutting-edge CAD/CAM systems. The concepts and constructions are then implemented through system-supported project planning and while considering the specifications and deadlines of our customers by means of well-functioning processes in a specialized department.