Extensive range of services

We have been your reliable development partner for decades and offer you customized complete solutions from a single source - from the first meeting to the finished product. Your benefit is our top priority. With a comprehensive range of services, we realize all your requirements and ensure maximum satisfaction.

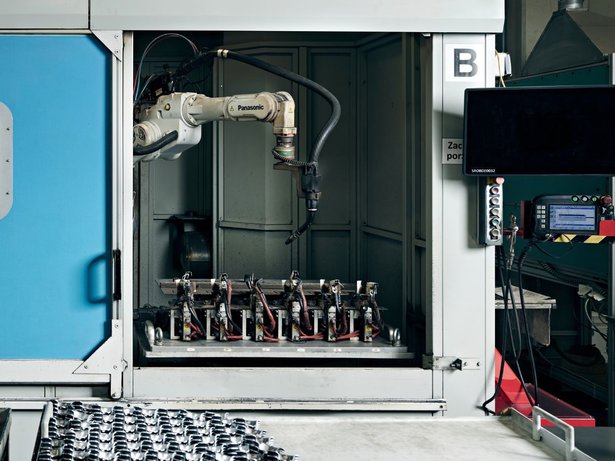

Innovative 2-part solution for motor housings

Through a combination of laser welding and a special mechanical cover connection, Schürholz has succeeded in supplying gas and watertight motor housings using the rolled process with a now patented two-part solution. With this innovative technology, we can achieve significant weight and cost advantages for our customers compared to conventionally deep-drawn motor housings. An additional advantage is that by using different material combinations of cover and housing - in terms of material types and thicknesses - we can realize new design approaches and produce in a more resource-efficient manner. This opens up completely new application possibilities, for example in areas such as electric window lifting systems, oil pumps, brake motors and industrial or household applications.

Our service that turns your vision into reality

With us, you get everything from a single source: from the initial inquiry to precise planning and implementation through to on-time delivery. Thanks to process-oriented project management, state-of-the-art surface finishing and individually developed logistics and supply concepts, we ensure smooth processes, top quality and absolute adherence to deadlines. Our strength lies in transforming your ideas quickly, efficiently and reliably into market-ready results. You benefit from short communication channels, expert advice and a dedicated team that is passionate about your vision. This saves you valuable time, avoids unnecessary interfaces and gives you exactly the product that meets your requirements - on time, reliably and in top quality.

Do you have any questions about our technologies or would you like individual advice?

Our experienced team will be happy to assist you and support you in all matters relating to our solutions. Whether you need detailed information on our offerings or help choosing the right technology, we are just one step away to provide you with expert assistance.

Don't hesitate to contact us - we look forward to supporting you!