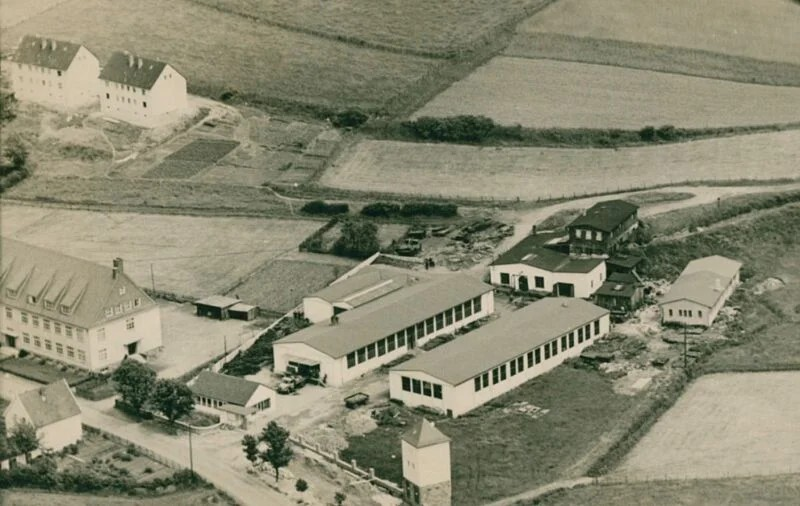

In 1985, the Plettenberg plant is relocated from Königsstraße to the Köbbinghausen industrial estate. The site area grew from approx. 10,000 m² to over 20,000 m² with an initial hall size of 4,200 m². The proportion of washers and standard parts was steadily reduced. From then on, the focus was on pressed, stamped and drawn parts. From the mid-1980s, the production of housings for cooling air motors is continuously expanded and up to 500,000 units are delivered each month. These motors are fitted with welded-on brackets with pressed-in screws for attachment to the cooling system. A welding shop is set up at the Würdinghausen plant in 1985.

At the same time, several DDS 600 discus double surface grinding machines are invested in, in order to be able to supply stamped parts and discs with the tightest tolerances and highest surface quality after the continuously planned exit from DIN disc production. Several million cylinder head washers for the automotive industry are produced annually, as well as spacers and shims. At the same time, the processing of fine blanking and cold extrusion parts with very tight flatness and thickness tolerances was carried out on a large scale.

Picture: Hans-Otto Schürholz in front of the administration building of the newly built plant in the Köbbinghausen industrial estate